https://www.keppelseghersbelgium.com/wp-content/uploads/2024/11/IMG_3771.jpg

1200

1600

KSBE_admin

https://www.keppelseghersbelgium.com/wp-content/uploads/2024/04/Keppel-Seghers1.png

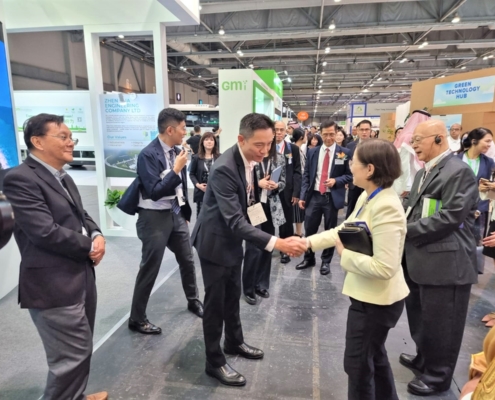

KSBE_admin2024-11-14 15:41:372024-11-27 21:03:03Keppel Seghers at Hong Kong Eco Expo 2024

https://www.keppelseghersbelgium.com/wp-content/uploads/2024/11/IMG_3771.jpg

1200

1600

KSBE_admin

https://www.keppelseghersbelgium.com/wp-content/uploads/2024/04/Keppel-Seghers1.png

KSBE_admin2024-11-14 15:41:372024-11-27 21:03:03Keppel Seghers at Hong Kong Eco Expo 2024Turning waste into win: Carbon capture’s role in sustainable energy solutions

1. Methane

Methane’s impact on climate change is 84 times higher than CO2 on a 20-year basis, and 18% of global anthropogenic methane originates from landfills due to the decomposition of the organic waste fraction. With 70% of the two billion tons of waste generated each year still being landfilled, it is undeniable that the current climate impact of landfilling is enormous. The emission factor of one ton of waste landfilled is between 600 and 5000 kg of CO2eq. Here lies a significant opportunity and urgency for the waste sector to reduce its climate impact by diverting waste from landfills to Waste to Energy (WtE) and recycling. The emission factor of WtE can even become negative by implementing Carbon Capture and Storage (CCS).

2. Negative emissions

A WtE facility produces two types of CO2: non-biogenic emissions from fossil-related waste such as non-recyclable plastics, and biogenic emissions from biogenic waste such as non-recyclable paper. Biogenic emissions are considered carbon neutral because they contain carbon that was initially present in the atmosphere. When a WtE facility is combined with a CCS facility, this CO2 is captured and stored permanently underground, meaning that this biogenic CO2 is not released into the atmosphere and is considered a negative CO2 emission. Such negative emissions can be used to offset emissions from hard-to-abate sectors like aviation.

3. Proven technical viability

CC is already being successfully implemented in several installations in the Netherlands and will be implemented in Norway following a detailed feasibility study.

4. Stable and reliable operation

It is a continuous process running 24 hours a day, seven days a week, with high availability (typically above 90%). This consistency is very beneficial and easier to manage for the CO2 capture process, whether the CO2 is to be stored or utilized.

5. Long-term assets

WtE plants are typically supported by long-term Waste Supply Agreements and Power Purchase Agreements and are inherently local, usually close to the waste source and energy offtake. WtE plants cannot be relocated to other geographies with lower energy or labor costs, for example.

6. Ready to be deployed

According to the National Academy of Sciences, Engineering, and Medicine, BECCS (Bio Energy Carbon Capture Storage) technology is ready for large-scale deployment. With 2500 WtE installations in operation and a capture efficiency of 90%, this could result in 378 million tons of CO2 captured per year instead of being released, and in 210 million tons of negative CO2 emissions.

7. Scale range

Due to its scale range from a few thousand tons to more than a million tons of yearly CO2 emissions, the WtE sector can be a very interesting sector to scale up and test new technologies.

8. Integration and synergies

The steam from the WtE plant can be used for the reboiler and reclaimer of the CC plant. As the steam is not sent to the condenser, spare cooling capacity becomes available. Synergies between the Carbon Capture and WtE process save CAPEX, OPEX, and space, and ultimately decrease the total cost of capturing CO2 (versus a standalone CC plant). Other potential synergies include combining the flue gas cleaning systems. The extent of integration will influence the total cost of carbon capture. The better and more optimised the integration, the lower the overall cost.

9. Cost competitiveness

Compared to the implementation of carbon capture in other industrial sectors, the cost in the WtE sector is very competitive.

10. Partially renewable energy

Reducing the CO2 concentration in the atmosphere is crucial for limiting climate change. As the carbon capture process is very energy-intensive, it is best to minimise the use of fossil energy for the capturing process. WtE produces partially renewable energy, which can be used in the capture process, making it more sustainable compared to other industrial sectors.

11. New business model for Waste-to-Energy

New financial incentives for developing CC in WtE are present. In the current economic model for a WtE project, the plant is financed by the gate fee charged to the municipality, by the sale of energy, and by the sale of recyclables from the process. When CC is integrated into the WtE sector, new sources of revenue become possible:

-

From the capture of fossil CO2 through a tax levy and/or emission allowances. The value of CO2 currently sits at around 100 €/ton, while the cost of capturing CO2 is continuously decreasing.

-

The negative emissions of WtE + CCS allow offsetting the emissions of other more challenging CO2 emitters. Today, such negative emissions can have a value of up to 200€/ton on the voluntary market.

-

From the sale of residual heat in a district heating or district cooling network. This is an effective way to recover heat from the CC plant.