https://www.keppelseghersbelgium.com/wp-content/uploads/2024/02/KSBE_00983.jpg

1000

1000

KSBE_admin

https://www.keppelseghersbelgium.com/wp-content/uploads/2024/04/Keppel-Seghers1.png

KSBE_admin2024-02-28 16:18:042025-01-23 10:44:24Sands of Change: Qatar’s Journey in Sustainable Waste Management

https://www.keppelseghersbelgium.com/wp-content/uploads/2024/02/KSBE_00983.jpg

1000

1000

KSBE_admin

https://www.keppelseghersbelgium.com/wp-content/uploads/2024/04/Keppel-Seghers1.png

KSBE_admin2024-02-28 16:18:042025-01-23 10:44:24Sands of Change: Qatar’s Journey in Sustainable Waste ManagementA state-of-the-art Waste-to-Energy project blended seamlessly with its natural environment

Location: Hong Kong

Category: Waste-to-Energy and Recycling Plants

Contract type: Design, Build and Operate (DBO)- 15 years

Construction period: 2021 – 2025

The Government of the Hong Kong Special Administrative Region has awarded a prestigious Design-Build-Operate (DBO) contract to Keppel Seghers and Zhen Hua Engineering for the construction of Hong Kong’s inaugural integrated waste management facility. This award was the culmination of a highly competitive international tender, reflecting the project’s significance and the expertise of the contracted companies.

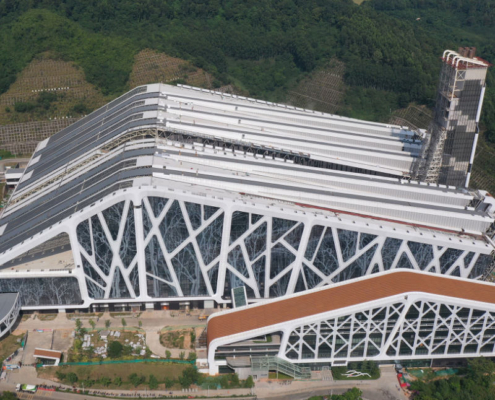

This state-of-the-art integrated waste management facility is designed on a reclaimed 16-hectare island, showcasing a harmonious blend of environmental responsibility and innovative technology. The facility is a centrepiece of sustainable waste management, featuring six waste-to-energy lines with an impressive total capacity of 3000 tonnes per day. These lines efficiently convert everyday waste into electricity, exemplifying a significant stride in recovered energy utilisation.

A core component of this facility, will incorporate Keppel Seghers’ renowned WtE technology. This technology is characterised by its air-cooled grate, heat recovery boiler, and an advanced combustion control system known as SIGMA. These features represent the cutting-edge in waste-to-energy processing, ensuring efficient and environmentally responsible energy generation.

In addition to its energy-producing capabilities, the WtE plant will employ Keppel Seghers’ advanced flue gas cleaning system. This system is designed to ensure that the plant’s emissions adhere to the stringent standards set by the European Union, which are recognised as some of the most rigorous international standards. This commitment to environmental compliance is a testament to the project’s dedication to sustainable and responsible waste management practices.

6

production lines

3K

tonnes waste per day

100K

households per year

Adjacent to these lines is a dedicated sorting and recycling line. This line has a capacity to process 200 tonnes per day, specialising in the segregation and recycling of glass, plastics, and both ferrous and non-ferrous metals. This meticulous sorting process not only reduces landfill waste but also ensures that valuable materials are reclaimed and reused.

The facility’s strategic location on a reclaimed island is protected by robust breakwaters, safeguarding it against marine conditions while enabling easy access for waste transport via the sea. The island is equipped with advanced port handling facilities, which streamline the logistics of waste arrival and processed material distribution.

In addition to its core waste management functions, the facility boasts ancillary services that further its self-sufficiency and environmental friendliness. Prominent among these is a desalination plant, which addresses the facility’s water needs by converting seawater into potable water. This is complemented by a wastewater treatment plant, which purifies water from the facility’s operations, ensuring that the facility’s impact on the surrounding marine environment is minimal.

1.2 Million tonnes of municipal solid waste

Annually, the facility impressively converts 1.2 million tonnes of municipal solid waste into a remarkable 480,000,000 kWh of net electricity. This substantial energy output is capable of powering up to 100,000 households in Hong Kong, marking a major contribution to the region’s energy needs. The facility operates with a contracted capacity of around 3,000 tonnes per day of municipal solid waste, effectively reducing the volume of waste by more than 90%. This dramatic reduction is not only a testament to the facility’s efficiency but also significantly minimises the environmental footprint of waste management.

In terms of environmental impact, the facility achieves an impressive reduction of approximately 440,000 tonnes of CO2 emissions annually. This considerable decrease in greenhouse gas emissions is pivotal in the fight against climate change and aligns with global environmental goal.

Complementing the waste-to-energy lines, the facility includes a Mechanical Treatment Plant with an annual capacity of 80,000 tonnes. This plant focuses on the sorting and recycling of glass, plastics, and metals. The separated materials are then transported back to various parts of Hong Kong for further processing into end products. This recycling loop not only diverts waste from landfills but also ensures that valuable materials are recovered and reused, closing the loop in the waste management cycle.

Unique

This project stands out not only for its scale but also for its revolutionary approach in the construction of waste-to-energy facilities. During the reclamation of the 16-hectare island, the waste-to-energy plant was meticulously preassembled in 15 modular components at a shipyard. These modules included six furnace-boiler units, six flue gas cleaning units, and three turbine generator sets. This modular construction approach facilitated the efficient transportation of these components by barge from the shipyard to the artificial island.

Upon arrival at the island, the modules were seamlessly transported to their final location using Self Propelled Modular Transporters (SPMTs). This innovative approach to construction not only expedited the assembly process but also minimized the environmental impact typically associated with such large-scale constructions.

Highlights

-

Largest modules’ dimensions: 60m height, 60m length, 30m width; each weighing 5000 tonnes.

-

Transportation of all modules by sea to the artificial island.

-

Peak construction periods saw 1000 workers deployed.

-

The project is expected to reduce waste disposal in Hong Kong’s landfills by 31%.