https://www.keppelseghersbelgium.com/wp-content/uploads/2024/11/IMG_3771.jpg

1200

1600

KSBE_admin

https://www.keppelseghersbelgium.com/wp-content/uploads/2024/04/Keppel-Seghers1.png

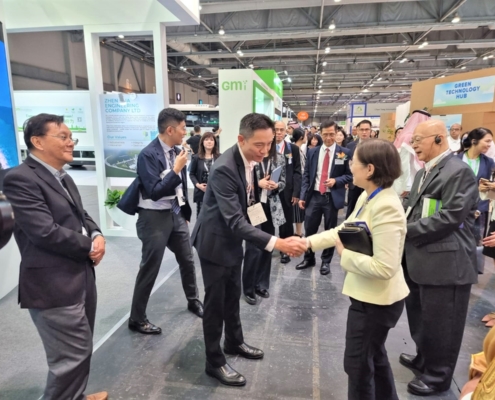

KSBE_admin2024-11-14 15:41:372024-11-27 21:03:03Keppel Seghers at Hong Kong Eco Expo 2024

https://www.keppelseghersbelgium.com/wp-content/uploads/2024/11/IMG_3771.jpg

1200

1600

KSBE_admin

https://www.keppelseghersbelgium.com/wp-content/uploads/2024/04/Keppel-Seghers1.png

KSBE_admin2024-11-14 15:41:372024-11-27 21:03:03Keppel Seghers at Hong Kong Eco Expo 2024In the scientific arena of environmental solutions, Waste-to-Energy (WtE) emerges as a compelling narrative of transformation, a testimony to humanity’s resolve to confront the escalating waste accumulation that looms over our civilisation. Through the insights of Benoit Englebert, Manager Business Development at Keppel Seghers Belgium, we explore how WtE transcends mere waste management, reinventing refuse as a cornerstone of sustainability. We explore the 12 reasons why Waste-to-Energy is good for us.

12 reasons why Waste-to-Energy is good for us

1. A 90% leap toward landfill independence

The story unfolds with a stark projection from the World Bank, predicting the global waste volume to reach a staggering 3.40 billion tons per year by 2050, while 70% of today’s waste, amounting to billions of tons, is still landfilled. In this context, WtE stands as a beacon of solution, with the power to reduce landfill reliance by up to 90%. This technology redefines waste management by mitigating issues associated with landfilling: the release of methane, air pollution, water contamination, groundwater degradation, and the dissemination of plastics and microplastics, recasting waste as a valuable resource for energy production or further recovery.

2. The climate change challenger: WtE’s dual impact

WtE asserts itself as a formidable force against climate change, operating on two decisive fronts. By diverting waste from landfills, it significantly reduces methane emissions: 1 ton of waste landfilled emits methane equivalent to 0.6 to 5 tons of CO2. Indeed, methane is 84 times more harmful to the climate than CO2 in its first 20 years in the atmosphere.

Moreover, with the potential to integrate carbon capture and storage, WtE facilities are on the path to net negative CO2 emissions, redefining the role of waste in our carbon equation. 1 ton of waste treated in a waste-to-energy plant emits 1 ton of CO2, while 1 ton of CO2 captured from a waste-to-energy plant generates 0.5 to 0.6 ton of negative CO2 emissions. Negative CO2 emissions or Carbon Dioxide Removal are key to reaching climate neutrality by 2050.

3. WtE’s campaign against landfill emissions

WtE’s role in air quality is profound, combating the array of harmful gases emitted from landfills, including methane, hydrogen sulfide, ammonia, and the numerous noxious gases from spontaneous landfill fires.

This technology not only redirects waste from landfills but also treats the resultant flue gases from WtE plants, ensuring that they meet the strictest industrial emissions requirements placed on any EU industry in terms of pollutants monitored, emission limit values and operating conditions. The air that emerges from the stack of a WtE plant is often cleaner than the urban environments they serve.

4. Guardians of the rivers and oceans

Worldwide, 33% of all generated waste is not collected and ends up in the environment, including rivers, lakes, and oceans. Floodplains and riverbeds often turn into common areas for illegal dumping. WtE intervenes by preventing waste, including plastic and microplastic waste, from reaching these waters, acting as a critical defense against the scourge of plastic pollution and protecting river and marine life.

5. The defender of groundwater

The silent threat of groundwater pollution by landfill leachate is countered by WtE’s strategic intervention. Landfill leachate, which contains many toxic and harmful substances such as heavy metals, persistent organic pollutants, and bacteria, has become one of the main anthropogenic sources of groundwater pollution. By intercepting waste before it becomes leachate, WtE shields our groundwater from a cocktail of hazardous substances, thus protecting ecological systems and human health.

6. Circular economy’s partner

In the circular economy, not every waste is recyclable: composite mixed materials, contaminated or dirty waste, and post-recycling waste are just not suitable for recycling. WtE emerges as a vital partner, converting non-recyclable waste into energy and salvaging materials for reuse.

It’s a model where one metric ton of non-recyclable waste, depending on the waste composition can yield 155 to 170 kg of useful mineral aggregates, 10 to 20 kg ferrous metals (steel and iron) and 4 to 10 kg nonferrous metals (aluminum, copper, etc…) or even precious metals like silver and gold, making non-recyclable waste partially recyclable.

7. Recapturing essential minerals: WtE’s contribution to sustainable construction

WtE is not merely about energy; it also contributes to the sustainable recovery of essential minerals. In 2018, around 96 million tons of waste (municipal, commercial, and industrial) were treated in Waste-to-Energy plants in Europe. The combustion process produced approximately 19 million tons of bottom ash, which is the incombustible residual part of the incinerated waste. From that bottom ash, 80 to 85% are composed of minerals that can be used in road construction and infrastructure, offering an eco-friendly alternative to virgin material like sand and gravel. In Denmark, around 99% of the bottom ash produced is recovered in road construction.

8. Metal recycling’s champion

In the story of metal recycling, WtE plays the role of a champion. If we consider all the Waste-to-Energy plants in Europe, it would be possible to recover almost 1.2 million tons of iron, enough to make 164 Eiffel towers, and about 250,000 tons of aluminum per year, the amount contained in around 8 billion smartphones. More anecdotally, out of 1 ton of waste, an average of 0.008 g of gold can be recovered: so, it would take about 650 Europeans’ annual residual waste to provide one golden ring.

9. WtE eliminates contaminated waste from recycling

WtE ensures the integrity of the recycling chain by filtering contaminated refuse, preventing harmful substances from entering the cycle of product manufacturing and safeguarding the quality of recycled materials. Bisphenol A, for example, an endocrine disruptor and reproductive toxic substance, is used as a color developer in thermal paper, typically used for sales receipts. Since thermal paper is typically recycled, it contaminates other paper products and, therefore, hampers the whole recycling chain. Another example is parabens, chemicals that scientific studies suggest can disrupt hormones in the body and harm fertility and reproductive organs, affect birth outcomes, and increase the risk of cancer, are used as preservatives to stop mold and bacteria growth that could spoil a product. If a plastic bottle containing parabens is recycled, it could contaminate other plastics, and even worse, come into contact with consumers.

In a WtE plant, those waste streams are destroyed thermically for some, or isolated with the flue gas treatment residues for others.

10. The power of clean steam from WtE

The narrative of WtE also celebrates the efficient generation of clean steam, a valuable commodity across industries. Depending on the demand, steam is typically produced at temperatures of 400-450°C and pressures from 40 to 65 bars. The efficiency of the steam production is typically between 80 and 95%, which means that 80 to 95% of the energy contained in the waste is converted into steam.

Steam finds versatile applications, from sterilization in healthcare to district heating systems and in the oil and gas industry. The three most common types of fuel used in steam boilers are coal, oil, and gas.

1 ton of municipal solid waste has the same energy content as 1 ton of lignite/brown coal or 250 liters of oil. In 2019, WtE plants in Europe produced the primary energy equivalent to 13,8 billion m³ of natural gas.

Using non-recyclable waste instead is an efficient way to decarbonize steam production and to localize fuel sourcing: two major challenges of our time.

11. WtE produces clean renewable electricity from waste

WtE serves as a lifeline of clean energy, converting the energy in non-recyclable waste into electricity with an efficiency between 25 and 35%. This process not only generates clean electricity but also supports localized energy distribution, advancing the move towards a sustainable energy model.

Flue gases from the process are chemically and physically cleaned to meet the strictest industrial emissions requirements placed on any EU industry in terms of pollutants monitored, emission limit values, and operating conditions. Moreover, the proximity of Waste-to-Energy plants to residential areas fosters the sector’s appetite for exemplarity.

According to the EU legislation the biodegradable fraction of municipal and industrial waste is considered biomass, thus a renewable energy source. The electricity output from WtE plants is about 50% renewable.

In 2019, WtE plants in Europe provided clean and partially renewable electricity to 20 million citizens.

12. WtE produces energy day and night

Renewable energies like solar and wind have become impressively cheaper—Bloomberg New Energy Finance estimates that solar and wind are the cheapest sources for 91% of the world’s electricity—and popular: this is excellent news for our planet. While renewable energy skeptics argue that because of their variability, wind and solar cannot be the foundation of a dependable electricity grid, in reality, it is entirely possible to sustain a reliable electricity system based on renewable energy sources plus a combination of other means, including improved methods of energy management and storage.

Waste-to-Energy produces clean and partially renewable energy 24 hours a day, 7 days a week. A waste-to-energy plant has an availability of typically more than 90%. Shutdowns are usually planned, and alternative productions can be anticipated. As such, waste-to-energy is part of those other means of producing energy that help the electricity grid cope with the variability of wind and solar energy.

References

-

Kaza, S.; Yao, L.C.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050. Urban Development; World Bank: Washington, DC, USA, 2018. Available at:

[https://openknowledge.worldbank.org/handle/10986/30317](https://openknowledge.worldbank.org/handle/10986/30317) (accessed on 16 September 2021).

-

CEWEP bottom ash factsheet, available at https://www.cewep.eu/bottom-ash-factsheet/

-

ESWET ‘Recovering the non-recyclable’, 2023. Available at https://eswet.eu/documents/recovering-the-non-recyclable-the-integrated-resource-recovery-facility/

-

ESWET factsheets, available at https://eswet.eu/document-cat/fact-sheets/

-

D, A. et al. Removal of heavy metals from synthetic landfill leachate in lab-scale vertical flow constructed wetlands. Science of the Total Environment 584, 742–750 (2017).

-

Y. Wang, J. W. Levis, and M. A. Barlaz, “An Assessment of the Dynamic Global Warming Impact Associated with Long- Term Emissions from Landfills,” Environ. Sci. Technol., vol. 54, no. 3, pp. 1304–1313, 2020.